"This is how you select wire ferrules? Wrong!

How to choose the right wire ferrule for terminal blocks?

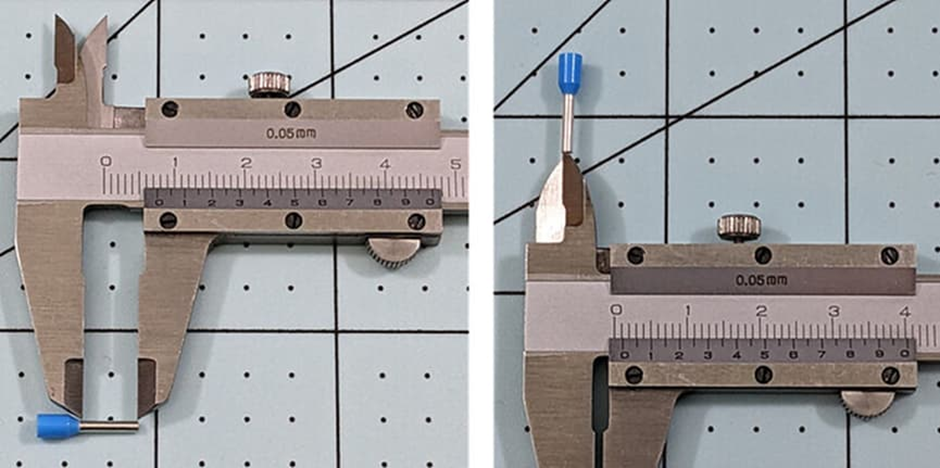

At times, we might be tempted to select a wire ferrule based solely on the length of the metal sleeve and its inner diameter, as shown in Figure 1. However, this would be a mistake. The first thing we should consider is the relevant regulations, particularly the UL 508A standard. This standard applies to industrial control panels designed for general industrial use, focusing on high-power electrical distribution and distinguishing between feeder circuits and branch circuits. It even extends to seemingly routine decisions, such as using wire ferrules for wire terminations.

These standards are critical—especially if you work in a UL 508A-certified panel manufacturing facility. Choosing the wrong component could lead to an inspector rejecting the panel, resulting in costly and time-consuming rework. Just like an uncertified car on the open highway, an uncertified control panel poses safety and reliability risks, along with serious liability concerns. A poor choice could injure someone or even start a fire."

Figure 1. Measuring the metal length and inside diameter of a terminal block.

Applicability of regulations to terminal blocks

The first and perhaps most important consideration when selecting terminal blocks is the crimping tool. Understand that the wire, terminal block, and crimping tool work as a unit. To comply with the standard, all three must be selected to the manufacturer's specifications. From a practical perspective, the terminal block and crimping tool are used together for a specific wire gauge. This is essential to ensure the mechanical integrity of the crimp and a low-resistance connection.

Tech Tips :

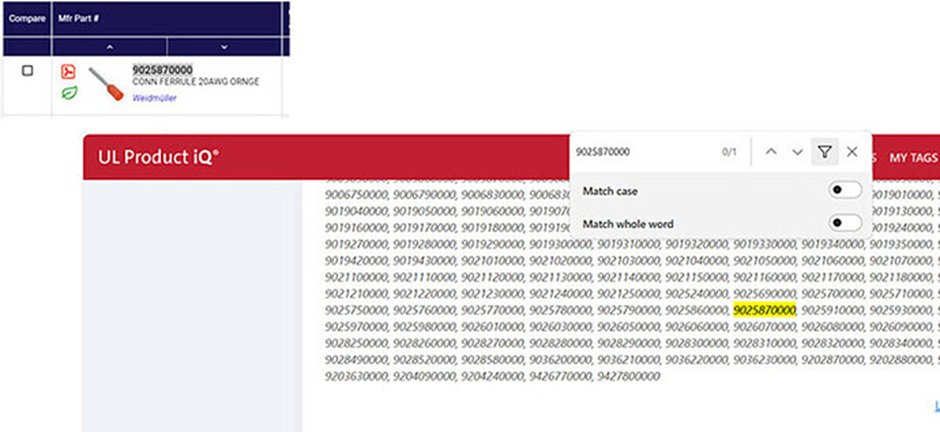

UL-approved parts can be identified using the specified tool, the data sheet for the specific part, or the authoritative UL Product Intelligent Query system (UL Product iQ, ulprospector.com). For each manufacturer, we can find a list of bare terminals, insulated terminals, and double-insulated terminals.

Connecting Terminal Blocks to Terminal Blocks

The next step is to determine the device to which your wire with terminal blocks will be connected. For example, take Schneider's TM241CEC24U plc.

TM241CEC24U plc

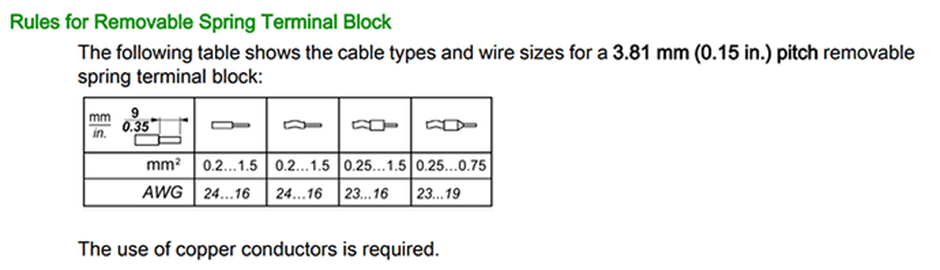

Like almost all devices of this type, it includes instructions for wiring the device. As shown in Figure 2, we can use stranded copper wire or terminal blocks. Unless double terminal blocks are used, only one wire is allowed per connection point. The diagram in Figure 2 tells us to strip 9 mm from the end of the wire. Similar information can be found for devices such as #terminal blocks and switches.

Figure 2. . Schneider Modicom plc rules for connecting spring-loaded terminal blocks.

Selecting the Appropriate Wire Ferrule

At this stage, we assume the required wire gauge and insulation rating are already known. The voltage rating determines the insulation thickness. To simplify the discussion, we also assume the wire has been pre-determined, as the wire selection process falls outside the scope of this article.

Let’s summarize what we know:

- The ferrule and crimping tool are interdependent and must be selected in accordance with the manufacturer’s guidelines.

- The exposed metal length of the ferrule is determined by the equipment it will connect to.

- The wire gauge and insulation thickness have already been defined.

With these parameters confirmed, we can proceed to select the appropriate components without repeatedly consulting UL Product iQ. Using DigiKey’s parametric search engine, we can filter for insulated ferrules compatible with 20 AWG wire and a pin length of 10 mm.

Next, let's take Weidmüller terminal block as an example. As shown in Figure 4, the selected 9025870000 model terminal block is recorded in the UL Product Intelligence Query System.

Fig. 4: Typical Weidmuller ferrule products cataloged in UL Product iQ database.

Finally, if you like this article, please share it with more friends! Remember to give it a thumbs up!